81 ford granada marquis (speedo, tacho and immobiliser)

With the build nearing completion it was time to interface the original Granada speedometer and tachometer with the Mercury PCM (Powertrain Control Module) and install the Mercury immobiliser system otherwise the PCM wouldn’t allow the engine to start.

The original Granada speedometer was cable driven and the Mercury speedometer was electronic so I had to use an adapter to convert the electronic speed signal from the PCM to a cable output to drive the speedometer,secondly the original Granada tachometer was calibrated for a four cylinder engine and now there was an eight cylinder engine sitting under the bonnet, finally due to the different final drive gear ratio I would need to recalibrate the speed signal from the VSS (Vehicle Speed Sensor) so the PCM would not get confused with the transmission shift schedules and engine mapping.

Speedometer

To drive the speedometer I installed a Dakota Digital ECD-200BT-5 electronic speed signal to cable drive adapter, this adapter fitted conveniently in the centre console behind the ashtray (remember when cars had ashtrays?) with a long enough cable to comfortably reach the speedometer head.

During initial testing using my laptop hooked up to the PCM and a GPS it showed with the original rear axle (3.89:1 gear ratio) there was an approximate 42%, speed error between what speed the car was actually going and what the speed the PCM thought the car was doing, which meant when doing a genuine 30mph (48kph) the PCM thought the car was travelling at 43mph (69kph), this upset the transmission shift schedules a little and activated the speed limiter at around 75mph (120kph), not a completely satisfactory situation. It was suggested by Gadget73 at LincolnsOnline (the premier forum for Lincoln enthusiasts) that maybe changing the transmission speedo drive would help with the speedo error, time to hit the calculator.

The known facts for the Mercury donor drivetrain …

- Axle ratio 2.73 to 1

- Tire size 225/60R16 = 758 turns per mile

- Green speedo drive gear, 17 teeth

Using those figures I calculated I have an 8 tooth drive gear in the transmission.

Drive gear 8 teeth x Axle ratio 2.73 x Tyre turns per mile 758 / 1000 = 16.55 tooth driven gear, close enough to 17 I think to be a correct calculation (A 7 tooth drive gear comes out at a 14.48 tooth driven gear)

The Granada known facts …..

- Axle ratio 3.89 to 1

- Tyre size 175/80R14 = 806 turns per mile

- 8 tooth speedo drive gear previously calculated

This calculates out as …

8 x 3.89 x 806 / 1000 = 25.08 tooth driven gear

As I already knew there was an approximate 42% speed error I could have just calculated ….

Current 17 tooth drive gear + 42% = 24.14 tooth driven gear, pretty close to my previous calculations allowing for some rounding up/down and a margin of error or two.

Conclusion

I would need a 24 or 25 tooth driven gear to correct my speed error, the biggest driven gear that seems to be available is a 23 tooth which from some research is very prone to failure sometimes within a 1000 miles, one manufacturer even states it is only good for 25,000 miles, which points to fitting the biggest available from Ford at 21 teeth.

A 21 tooth driven gear would go some way to correcting my speedo error but it would still leave around a 17% inaccuracy, whilst I am not overly worried about this as far as the speedo is concerned as I can correct that when I buy an electronic signal to mechanical cable adapter, I am concerned about how this inaccuracy is affecting the engine mapping and shift schedules.

One other thing changing the rear axle for one from a 2.8 litre (170ci) Granada with lower ratio at 3.45 to 1 this would further reduce the speedometer error and engine speed at a given RPM which I feel is currently a little high for comfortable freeway cruising.

If I use a 3.45 axle ratio in the speedo drive gear calculations I get 22.24 teeth which I think using a Ford 21 tooth gear would be acceptable.

So there you have it, I need a 21 tooth (Purple?) speedo drive gear (one was obtained a fitted).

Tachometer

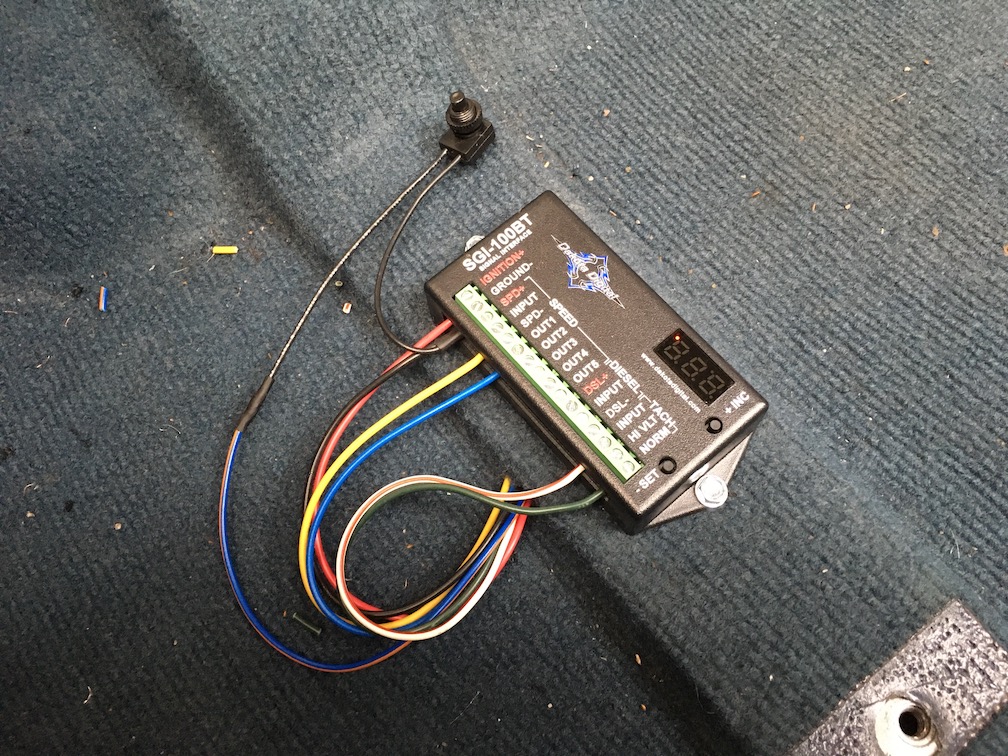

The tachometer was much simpler, I fitted a Dakota Digital SGL-100BT universal speedometer and tachometer interface under the driver’s seat, I took a signal from cylinder five ignition coil for the RPM input and connected it in series to the VSS for the speed input, all that was now required was to recalibrate the signals using the free set up application from Dakota Digital.

Immobiliser

The Mercury donor car was fitted with Ford’s PATS (Passive Anti-Theft System) immobiliser. The PATS on the Mercury was controlled by a stand alone module (another good reason the Mercury makes an ideal donor car) as opposed to being intergrated into the instrument cluster as in other mnodels at the time. The PATS works by a transciever mounted around the ignition key barrel that reads a chip in the key, the transceiver sends a signal to the PATS module that conpares to code in the key to the one stored in its memory, if the keycode matches the PATS module sends a signal to the PCM to allow the engine to start, the keycode changes everytime you start the car for added security.

I mounted the PATS module in the centre console and temporarily taped the Mercury ignition key to the transceiver hiding it under the dashboard, in the future I am going to investigate whether there is a chipped key available with the same profile as the Granada, then I can fit the transceiver around the ignition barrel and have a fully functioning immobiliser.

more information about the ford granada marquis

Please follow the links below to find out how the 1981 Ford Granada Marquis was created. (Click on pictures to see at full size)

- The concept (Find out why Granada Marquis here)

- Build preparation

- Fitting the engine

- Transmission & driveline

- Brakes, steering & suspension

- Exhaust

- Speed control

- Engine cooling & air conditioning

- Speedometer, tachometer & immobiliser

- Wiring & wiring diagrams

- Miscellaneous

- Specifications

- Gallery of finished vehicle

- Back to Derecks MOT Centre homepage

- Back to the Ford Granada Marquis home page